[2008-12-015] 2 piece Hoffman clamp

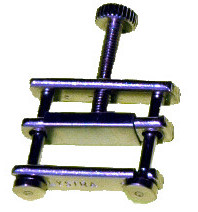

So-called "Hoffman clamps," shown below, are extraordinarily handy bits of lab kit. The screw is turned to compress a piece of flexible tubing between two bars, and may be thus be used to completely stop or simply to regulate flow of gas or liquid through such tubing. They are importantly distinguished from simple "pinchcocks" in that the screwing action of the Hoffman clamp allows adjustment of the rate of flow infinitessimally from full open to full stop. In amateur apparatus, a Hoffman clamp can often take the place of a glass or teflon stopcock, which is a much more sophisticated and expensive bit of apparatus. Hoffman clamps are inexpensive and can be had easily from various on-line vendors.

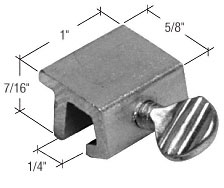

Still, I've spent some time thinking about how Hoffman clamps could be improvised in the home shop. Obviously, it's not a complex machine and any semi-competent machinist or mechanic could put one together, if necessary, without much difficulty. I've just been looking for a short-cut or readymade approach, and have had a couple of ideas that ended up failing. The most promising was the use of thumbscrew sash locks for windows as improvised Hoffman clamps; turns out the parallel bars in a traditional Hoffman clamp are basically essential to the design. Simply confining the tubing in a hollow channel and compressing it directly with a screw does not provide an adequate seal.

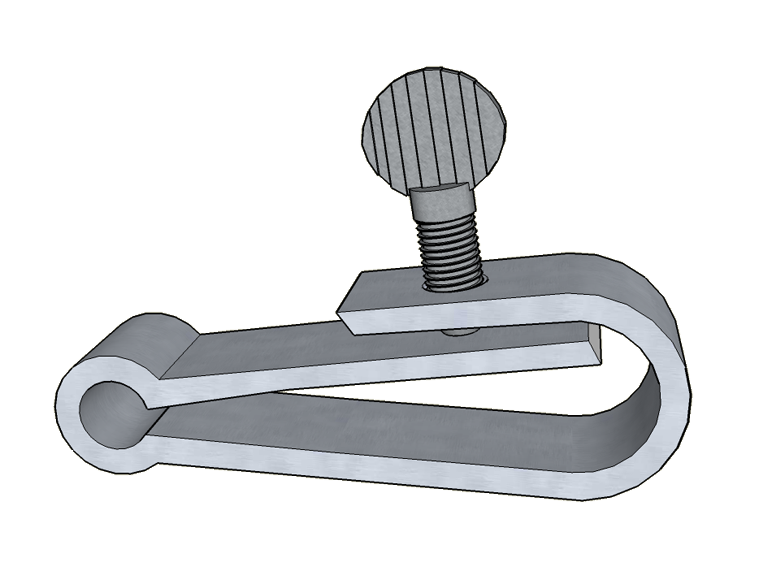

All of which thinking has lead me to consider how the mechanism of a Hoffman clamp could be reduced to its bare essentials. The concept drawing at the top of this page is the result. It almost qualifies as a readymade solution: If one could find a spring snap hook with as much overlap as required between the spring arm and the retaining hook, and as much depth and thickness as would be necessary to adequately support the threaded hole for the thumbscrew, it could be made easily from off-the-shelf components. In fact, no such spring snap hooks exist, at least not to my knowledge, and they would have to be manufactured expressly for this purpose. Still, this might be a costworthy simplification of the Hoffman clamp on a manufacturing scale.

last modified 2008-12-15